China Stainless Steel Oscillating Band Supplier – SSBANDING’s Innovation for Automated Production Lines

As a leading China stainless steel oscillating band supplier, SSBANDING delivers 20x-length stainless steel oscillating coils with 20% productivity gains. Explore our patented edge-smoothing technology and zero-waste solutions.

Table of Contents

Introduction: Redefining Efficiency in Industrial Material Handling

In the era of smart manufacturing, the demand for high-performance stainless steel oscillating bands has surged across automotive, electronics, and packaging industries. SSBANDING, a pioneer in cold-rolled stainless steel strip processing, introduces a game-changing solution: the ultra-long oscillating band coil designed to minimize downtime and maximize output for automated production systems.

This article dives into the engineering breakthroughs behind SSBANDING’s oscillating band technology, its naming rationale, and why global manufacturers are transitioning from conventional steel strips to this innovative format.

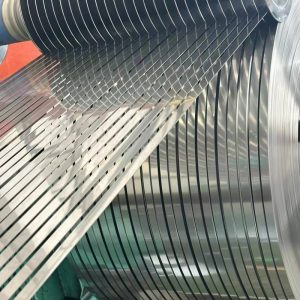

Chapter 1: What is a Stainless Steel Oscillating Band?

The term “oscillating band” derives from its unique operational pattern in automated machinery. Unlike traditional coils that require frequent reloading, our welded multi-strip oscillating coil moves in a controlled back-and-forth motion (oscillation) during unwinding. This design:

- Eliminates abrupt stops during material feeding

- Enables seamless integration with robotic arms and CNC systems

- Reduces friction-induced heat through optimized tension control

SSBANDING’s oscillating band is precision-crafted from Grade 304/316L cold-rolled stainless steel, with widths ranging from 2.5mm to 50mm and a single coil length equivalent to 20 traditional coils (up to 5,000 linear meters).

Chapter 2: Core Technologies Behind SSBANDING's Oscillating Bands

1. Seamless Multi-Strip Welding Process

Our proprietary continuous welding system joins individual steel strips end-to-end with:

- ≤0.1mm weld seam tolerance

- X-ray inspection for internal defect detection

- Red epoxy marking (20cm on both sides) for visual weld-point identification

This ensures ≤3 weld joints per 500kg coil, a benchmark unmatched by competitors.

2. Burr-Free Edge Processing

SSBANDING’s automated edge-rounding technology achieves:

- Surface roughness (Ra) ≤0.4μm

- 360° smooth edges to prevent conveyor belt abrasion

- Electropolishing option for food/pharma-grade applications

3. Single-Pass Production System

Unlike conventional multi-stage processing, our patented integrated line completes:

- Slitting → Deburring → Welding → Coiling → Packaging

in one uninterrupted cycle, eliminating: - Intermediate handling scratches

- Oil contamination from transfer equipment

- Post-production straightening requirements

Chapter 3: Quantifiable Benefits for Industrial Users

Productivity Metrics

Parameter | Traditional Coil | SSBANDING Oscillating Band | Improvement |

Coil Change Frequency | Every 2 hours | Every 40 hours | 95% ↓ |

Scrap Rate (Start/End) | 3-5% | 0.8% | 84% ↓ |

Annual Output per Line | 2,500 tons | 3,650 tons | 46% ↑ |

Cost-Saving Analysis

- Labor: Automated overhead crane loading cuts manual handling by 70%

- Energy: Reduced machine start-stop cycles save 15% power consumption

- Material Yield: Precision slit-to-width minimizes edge trim loss

Chapter 4: SSBANDING's Manufacturing Capabilities

Production Scale

- 2 dedicated oscillating band lines with 10-ton/day capacity

- Coil weight customization: 13kg to 1,000kg (±2% tolerance)

- 48-hour turnaround for standard specs

Quality Assurance Protocols

- ISO 901:2015-certified welding procedures

- Real-time thickness monitoring via laser micrometers

- Salt spray testing up to 1,000 hours for corrosion resistance

Chapter 5: Industry-Specific Applications

Automotive Battery Assembly

- Tesla-style automated cell stacking lines

- Zero-particulate edges prevent short circuits

Food Canning Systems

- Electropolished coils meet FDA 21 CFR 175.300

- 50% faster line speed vs. polymer belts

Semiconductor Wafer Transport

- Non-magnetic 316L variants

- ESD-safe surface treatment

Why Choose SSBANDING as Your Oscillating Band Partner?

- Price Competitiveness: 12-18% lower than EU/US suppliers via vertical integration

- Technical Exclusivity: 3 patents in coil welding and edge finishing

- Sustainability: 98% recyclable steel with carbon-neutral production roadmaps

Conclusion: The Future of Automated Material Feeding

As the only Chinese manufacturer mastering end-to-end oscillating band production, SSBANDING empowers factories to achieve Industry 4.0 readiness. Our 20x-length coils aren’t just a product – they’re a productivity revolution welded into a single, intelligent package.

Contact SSBANDING today to request free samples and transition to waste-free, high-yield production.

Tags

- Stainless steel oscillating band supplier

- China oscillating coil manufacturer

- Cold-rolled stainless steel strip

- Automated production line solutions

- Long-length steel coil

- Burr-free edge technology

- High productivity steel band