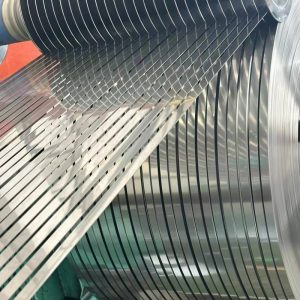

202 vs 201 Stainless Steel Coil: Key Differences for Industrial Applications

As a leading manufacturer of stainless steel banding solutions, SSBANDING understands the critical role material selection plays in product performance. This article explores the key differences between 202 and 201 stainless steel coils to help you make informed decisions for your projects.

Table of Contents

1. Chemical Composition

The fundamental distinction lies in their alloy composition:

- 202 Stainless Steel: Contains higher manganese (7.5-10%) and nitrogen to compensate for reduced nickel content (4-6%). Chromium levels range between 17-19%, enhancing oxidation resistance.

- 201 Stainless Steel: Features lower manganese (5.5-7.5%) and minimal nickel (1.02-1.28%), making it a cost-effective alternative.

This compositional variance directly impacts their mechanical and functional properties.

2. Corrosion Resistance

- 202 Coil: Superior resistance to acidic environments (e.g., food processing plants, chemical industries) due to its balanced chromium-nickel-manganese matrix. Ideal for coastal or chloride-exposed applications.

- 201 Coil: Suitable for mild environments (e.g., indoor appliances) but prone to pitting in high-moisture or salt-rich conditions.

3. Hardness & Magnetic Properties

- Hardness: The elevated manganese in 202 grants higher tensile strength (≥515 MPa vs. 201’s ≥450 MPa), making it preferable for structural components.

- Magnetism:

- 202: Exhibits slight magnetism after cold working.

- 201: Typically non-magnetic in annealed states.

4. Welding & Fabrication

- 202 Coil: Offers better weldability with reduced risk of carbide precipitation, ensuring durable joints for automotive or construction uses.

- 201 Coil: Requires precise heat control during welding to avoid brittleness.

5. Cost & Applications

Factor | 202 Stainless Steel Coil | 201 Stainless Steel Coil |

Cost | 15-20% higher due to manganese and nickel | Budget-friendly for mass production |

Typical Uses | Architectural cladding, automotive trim, food processing equipment | Kitchenware, household appliances, decorative trims |

Why Choose SSBANDING?

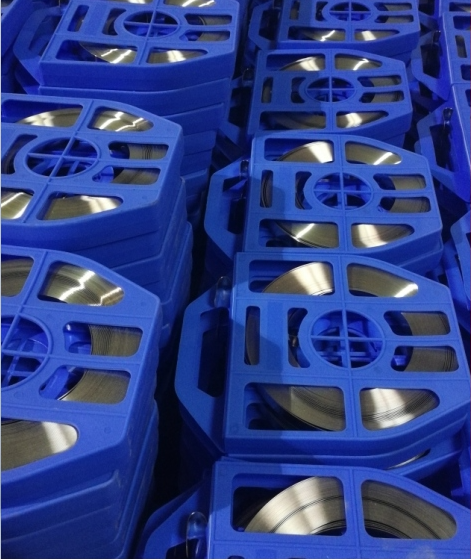

At SSBANDING, we tailor stainless steel banding solutions to your needs:

- Material Expertise: Customized alloy selection for corrosion resistance, strength, and cost efficiency.

- Global Compliance: Products meet ASTM, EN, and JIS standards.

- Certified Quality: ISO 9001 and CE-certified manufacturing.

Tags

Optimized Keywords:

- 202 stainless steel coil vs 201

- Corrosion-resistant stainless steel banding

- High-manganese stainless steel applications

- Cost-effective stainless steel grades

- Welding performance of 202 stainless steel

By integrating these insights, your projects can achieve longevity and cost efficiency. Contact SSBANDING today to discuss custom stainless steel solutions tailored to your industry needs.

References:

: Comparison of 202 with 304/316/201 (2024)

: Applications of 201/202 coils in architecture and appliances (2024)

: Pricing data for 201/202 coils (2022)

: Corrosion test results for 201/304/316 (2025)

: Mechanical properties and welding guidelines for 201 (2025)