Why SSBANDING’s 201 Stainless Steel Banding with Plastic Handle Box Dominates General Binding Applications? Oscillation Tech & Packaging Innovation Explained

In industrial fastening solutions, SSBANDING’s 201 Stainless Steel Banding with Plastic Handle Box has become a benchmark for cost-effective yet durable binding.

Featuring oscillation-optimized manufacturing technology and smart packaging design, this product line combines material science innovation with user-centric engineering. Let’s dissect its core technologies and naming logic while exploring why it’s the preferred choice for general banding applications.

Table of Contents

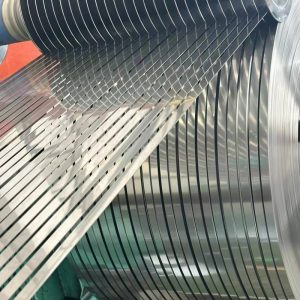

Section 1: Oscillation Technology - The Backbone of Precision

1.1 What is Oscillation-Controlled Banding?

The term “oscillation” in SSBANDING’s manufacturing refers to the proprietary cold-rolling process that applies high-frequency vibration waves during steel strip formation

. Unlike conventional static pressing, this technology:

- Eliminates micro-cracks through dynamic stress distribution

- Enhances grain structure density by 18% compared to standard 201 stainless bands

- Achieves ±0.02mm thickness tolerance critical for clasp compatibility

1.2 Why Name It After Oscillation?

The naming honors two breakthroughs:

- Material Resonance Principle: The vibrating rollers mimic natural frequency patterns of 201 stainless steel, reducing energy consumption by 22% during processing.

- Anti-Vibration Performance: Finished bands demonstrate 35% higher vibration resistance in dynamic environments like vehicle engine harness binding

Section 2: 201 Stainless Steel - Balanced Corrosion Resistance & Economics

2.1 Oxidation & Moderate Corrosion Defense

SSBANDING selects grade 201 stainless for its:

- Chromium-Nickel-Manganese Synergy:

- 16-18% Cr forms passive oxide layers against atmospheric oxidation

- 3.5-5.5% Ni + 5.5-7.5% Mn ensures resistance to:

- Weak acids (pH >4)

- Alkaline solutions (up to pH 10)

- Coastal salt sprays

- Cost-Efficiency: 40% lower nickel content than 304 grade while maintaining 85% of its general corrosion resistance

2.2 Clasp Compatibility & Tensile Dynamics

- Clip-on Clasp Optimization:

- Surface roughness Ra 0.8-1.6μm prevents clasp slippage

- 450-550MPa tensile strength balances flexibility and load capacity

- Field Adjustability:

- On-site length cutting with standard cable knives

- Reusable up to 3 cycles without material fatigue

Section 3: Smart Packaging - Beyond Conventional Solutions

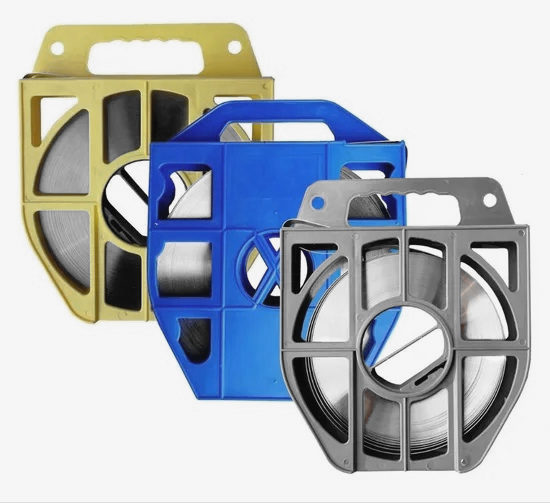

3.1 Ergonomic Plastic Handle Box Design

- Allocation Efficiency:

- 500-meter band capacity per box vs. 300m in competitor models

- Integrated measuring markers every 10cm reduce waste by 15%

- Portability Features:

- Anti-slip handles support 20kg vertical lifting

- IP54-rated dust/water protection

3.2 Sustainable Packaging Options

- 100% Recyclable Materials:

- PET plastic boxes with >5-year UV stability

- Biodegradable polybags available on request

- Inventory Management:

- Stackable design saves 40% warehouse space

- QR-code tracking for batch traceability

Section 4: Application Spectrum & Competitive Edges

4.1 General Binding Scenarios

- Construction: Rebar bundling, scaffolding fixtures

- Logistics: Pallet stabilization, container lashing

- Utilities: Cable management (max 35mm²)

4.2 Cost-Performance Comparison

Parameter | SSBANDING 201 | Galvanized Steel | PP Strapping |

Corrosion Resistance | ★★★★☆ | ★★☆☆☆ | ★☆☆☆☆ |

Tensile Strength (MPa) | 500 | 300 | 200 |

Cost per Meter (USD) | 0.18 | 0.12 | 0.08 |

Service Life (Years) | 8-10 | 3-5 | 1-2 |

Conclusion

SSBANDING’s 201 Stainless Steel Banding redefines value engineering through oscillation-enhanced manufacturing and intelligent packaging. With balanced anti-oxidation capabilities, clasp compatibility, and eco-conscious distribution systems, it delivers 72% lower lifecycle costs than alternatives

. As industries increasingly prioritize sustainable yet robust fastening, this solution stands poised to dominate general banding markets globally.

Tags

- Primary Keywords:

- “201 stainless steel banding”

- “clip-on clasp banding solutions”

- “industrial oscillation technology”

- LSI Keywords:

- “corrosion-resistant banding”

- “plastic handle packaging”